Design for unknown requirements at the Dakar Rally

Design for unknown requirements at the Dakar Rally

Demanding charging process in complex off-road operation

Intelligent energy management with recuperation during braking

The high-voltage battery is located centrally in the drive and literally in the middle of the Audi RS Q e-tron. It embodies the heart of the innovative electric drive with energy converter. Audi intends to use it to set the next milestone in the world’s toughest rally and prove “Vorsprung durch Technik” in the desert as well.

“With our drive configuration in the RS Q e-tron, Audi is a pioneer in the Dakar Rally,” says Lukas Folie, the high-voltage battery engineer. “Defining the challenges for this type of competition was very demanding. There are simply no empirical values in motorsport for such a concept and for this type of endurance competition.

Design for unknown requirements

Compared to the Formula E World Championship, which Audi last contested with a battery-electric drive, the standards at the Dakar Rally are different: daily stages of many hundreds of kilometers, the enormous driving resistance in the soft desert sand, plus high outside temperatures and a minimum vehicle weight set by the regulations at two tons are extreme values in motorsport.

“It is not possible with today’s battery technology to realize an all-electric BEV off-road vehicle for the Dakar Rally under these conditions,” says Lukas Folie.

The engineering team led by Axel Löffler, Chief Designer of the RS Q e-tron, therefore had to define basic benchmarks for the overall concept of the vehicle with electric drive and energy converter without any previous empirical values. Due to the short project development time, Audi relied on proven cell technology.

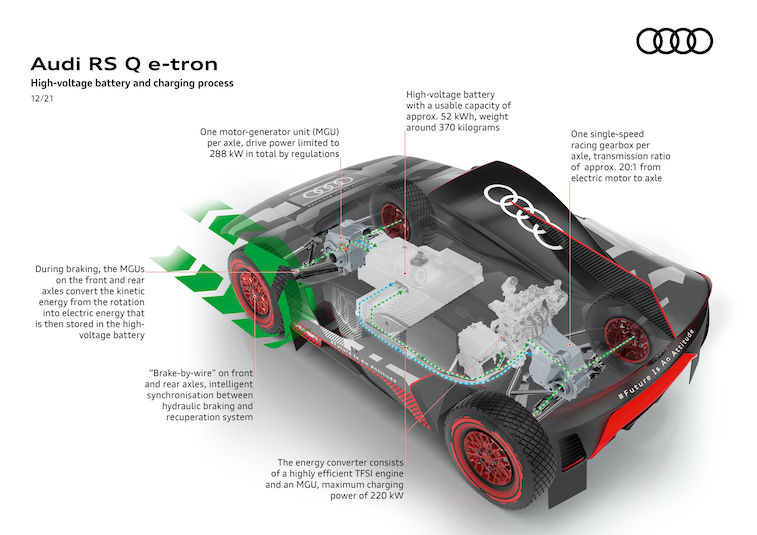

The capacity of the high-voltage battery is 52 kWh and is therefore sufficient for the maximum expected requirements on each leg of the rally. The weight of the high-voltage battery including the cooling medium is around 370 kilograms.

Durability and high energy density

Durability and high energy density

The required energy capacity and performance, as well as control and safety mechanisms, made Audi resort to proven round cells as the basis of the high-voltage battery. The battery system is designed in such a way that Audi Sport drivers Mattias Ekström, Stéphane Peterhansel and Carlos Sainz do not feel any difference between a new and a used battery.

Demanding off-road charging

When the rally drivers leave the bivouac in electric drive on the morning of each stage with a charged high-voltage battery, a highly complex control system begins. Only a few minutes before the start of the stage do the teams learn any details about the route at all when the roadbooks are handed out.

The Audi RS Q e-tron with its innovative drive must always be prepared for all conditions in terms of distances, speeds, difficulty of the terrain and other factors. The engineers and electronic technicians have programmed algorithms to keep the State of Charge (SoC), i.e. the charge level, within defined ranges depending on the energy demand.

Energy extraction and battery recharging are always in balance over defined distances. If, for example, a difficult dune passage with high driving resistance requires maximum energy for a short time, the state of charge drops within a controlled range. The reason:

The drive power of the engine-generator units on the front and rear axles is limited to a maximum of 288 kW in total under the regulations. However, the energy converter can only provide a maximum charging power of 220 kW.

In extreme cases, therefore, consumption is briefly higher than energy generation. “Something like this is possible for a limited time,” says Lukas Folie. “But over a longer distance, it always results in a zero-sum game: We then have to regulate the power consumption down so that the battery’s state of charge remains within a corridor. The absolute amount of energy available on board must be sufficient to cover the day’s leg.”

Energy recovery as an important factor

In order to realize maximum efficiency, Audi is also relying on a principle in the desert that has already been used in the Le Mans sports cars and in Formula E: The RS Q e-tron recovers energy during braking. The MGU units on the front and rear axles can convert the rotational movement of the wheels into electrical energy.

The aim is to recuperate the maximum energy. The power flow in this reverse direction is not subject to the same power limitations as when accelerating. What sounds so simple requires a complex Intelligent Brake System (IBS). It combines the hydraulic braking function with the electric regenerative brake.

Efficient on the move

Thanks to this targeted design, the RS Q e-tron has an exceptional position in the starting field. This applies not only to the basic system topology of all assemblies but also to the energy control system.

Although it has to move a larger mass due to the regulations, the RS Q e-tron manages with less energy than the competition. The smaller tank volume for the energy converter specified in the regulations proves that the rally car with the four rings is very efficient.